The No. 98 / No. 99 Side Rabbet Plane Project Story

Posted by Michael Zimmerman on 6th Jan 2023

The No. 98 / No. 99 Side Rabbet Plane Project Story

I have always found the hardest part to starting a complex project is located between the dream and reality or the ever difficult “first step”. It is the point were planning gets put to the test and one gets to glean wisdom and knowledge from both the plans surviving remnants and those pieces of the plan that utterly fail. So covid is mostly behind us but the headaches that came with it still influence everyone’s planning including my simple plan to make great tools. I fully expected turns and twists in this economic environment, and I have not been disappointed. From extended timelines with various vendors of raw materials and shop supplies to defective material that lead to a month and a half set back, many lessons and observation have been made.

One lesson that sticks out is the art of perseverance. I think I grew accustomed to the time were my go to endmill was always in stock or I could call up for raw material and it would be ready to go the next day. I had also grown accustomed to consistent and reliable quality, but we are in a new era of pressure and constraints on all producers which affect quality and availability. Persevere we must so I took that dreadful yet exhilarating first step to simply start the project! I began by defining what I wanted in the plane I was to create. My tool design philosophy is that it needs to honor the past while injecting some unique character and a contemporary flare. It needs to improve on the design in measurable ways either practically, aesthetically, or in the precision of manufacture. Of course, it needs to be beautiful to me or why bother making it. It was really with these basic parameters in mind that I set about making the Ember 3 No. 98 / No. 99 side rabbet plane set.

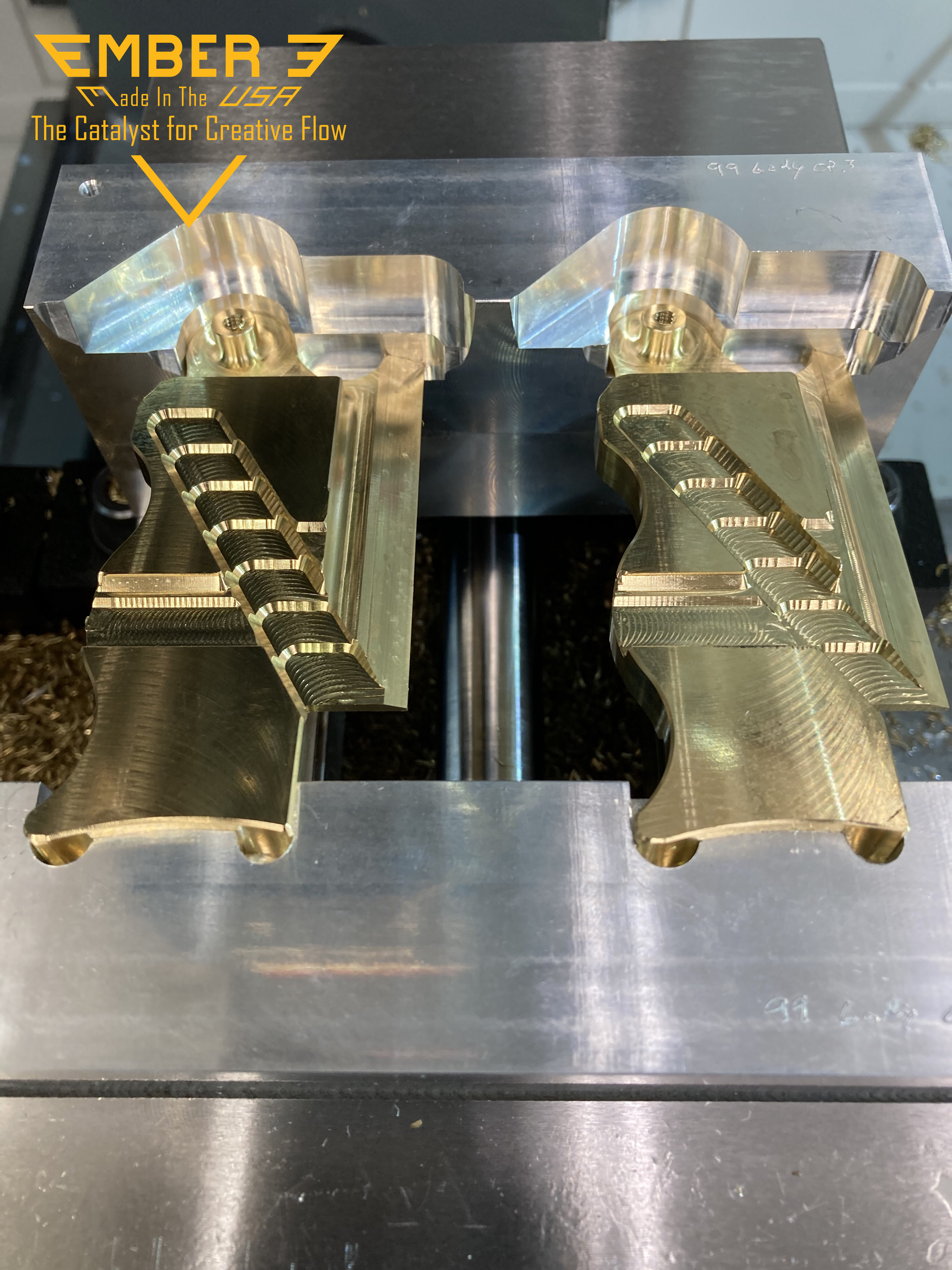

I’m not a big fan of castings so I set out to machine the No. 98 / No. 99 using billets of c46400 naval brass which is both tough and more resistant to corrosion than other brass. One of my gripes against the Stanley No. 98 that I own is that the depth adjuster is crooked, yep, square to nothing. Since I have observed this in other No. 98’s and No.99’s over the years, I decided to improve the depth adjuster by machining a slot which keeps it consistently level and parallel. Consequently, the depth adjuster also received a makeover and when combined with the billet body design, added one extra ounce which gave it a little more heft and those contemporary lines that I like. I love the look and feel of cut knurling either by machine or file but it is both time and labor intensive, so the brass knobs were made more contemporary in shape as well (and I really do not like pressed knurling all that much). The cutting blade was simply made to current industry blade standard of A2 tool steel 60-62 RC with a cryo treat. As for the wood knob, well that was a source of a major setback. Due to the CITES treaty, my plan was to use a high quality laminated and died birch product common in the firearms industry that closely mimicked rosewood / cocobolo. What I found out in practice was that thicker pieces needed for knobs and totes are prone to de-lamination (even when using sharp tools and sharp sandpaper to avoid excess heat buildup) and much time and money was wasted on this portion of the project. So, working through all phases of the grieving process in expedient time, I unceremoniously dumped the hole lot of hundreds of knobs that developed cracks weeks after completion in the garbage can and lived to fight another day. I made the switch to cherry wood which was is plenty strong for the purpose, beautiful, readily available, and not included in the CITES treaty.

Once I had completed the run of No. 98 / No. 99 side rabbet plane sets, I set about the other aspects of starting a small company like writing this article, building a website, setting up emails, social media accounts, payment processing, shipping and the like. Needless to say, I have spent quite a bit of time in this set up stage and miss the shop. Thankfully, I will soon get most of my shop time back as maintaining the admin side of things is far less demanding than creating them from scratch.

As the No. 98 / No. 99 side rabbet plan product launch goes into full swing, I’ll already be prototyping some more planes and you will get to read about those in a future blog.